Two weeks ago, I was invited by Nomos to attend their annual forum held in the heart of German watchmaking, the town of Glashütte. My visit to the Nomos Forum began with a tour of the brand’s manufacturing facilities. There are several of them around Glashütte and one few km away from the town.

Nomos chronometry building in Glashütte

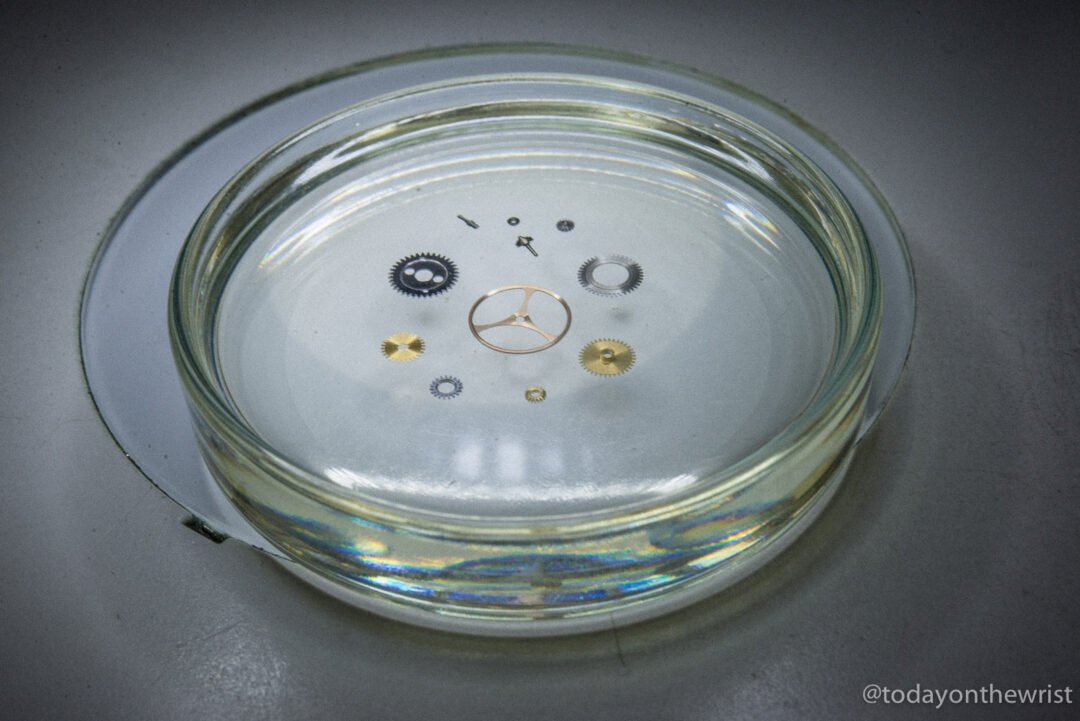

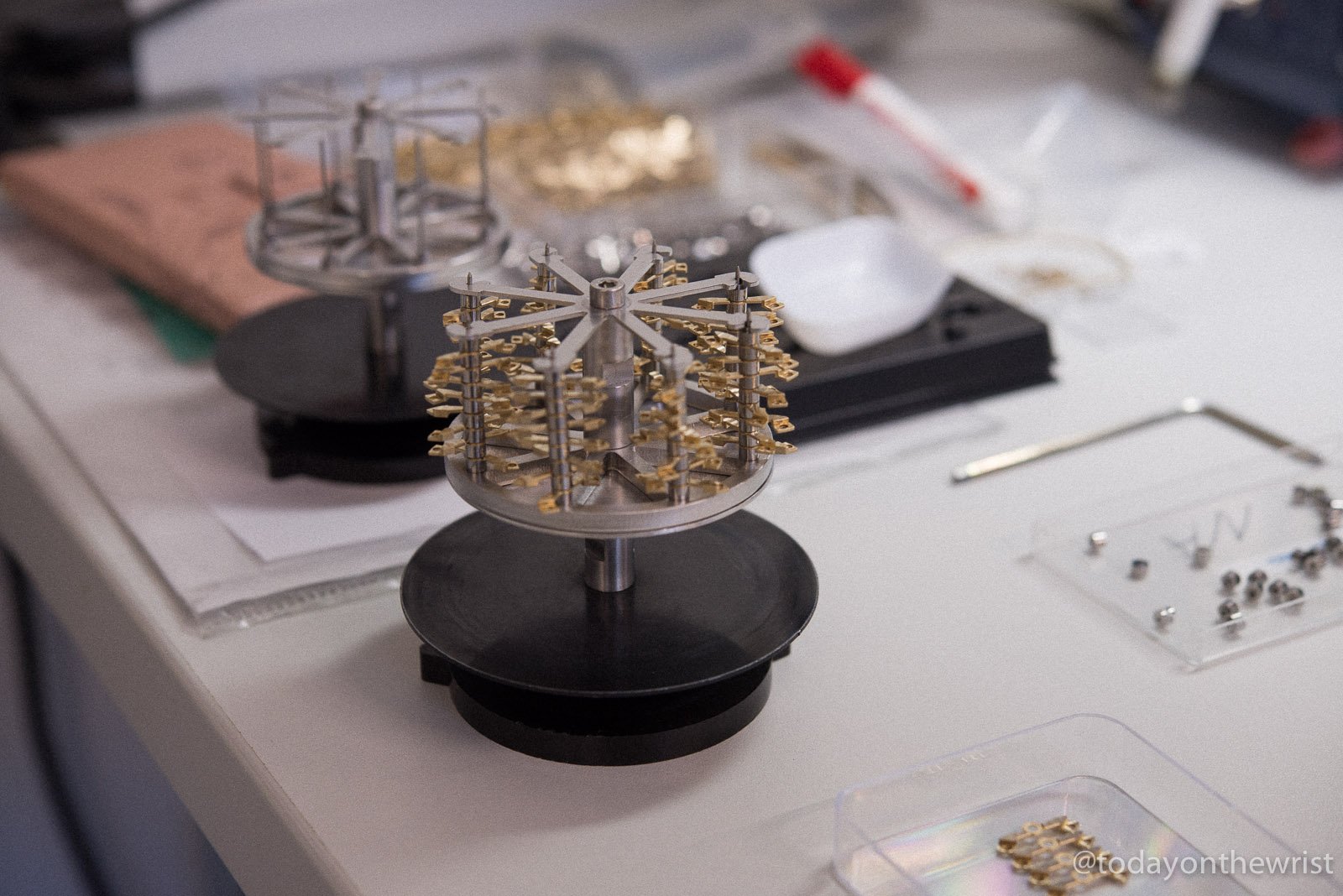

Our first stop was the chronometry building, which houses various watchmaking workshops, including the department responsible for assembling the Nomos swing system. The Nomos swing system, also commonly known as the escapement, is the heart of any mechanical movement. Without an escapement, it is impossible for a watch to tick and tock. In 2014 Nomos introduced the in-house built escapement and called it Nomos swing system.

Escapements are incredibly fine components; no other part within a mechanical watch reserves such a small margin of error. The balance and the balance spring must operate flawlessly in relation to each other’s individual properties; the escape wheel teeth must be perfectly concentric—the tiniest miscalculation means the entire escapement will not function at all. All this magic of assembling the swing system is happening in the room, that you see on the pictures above, all by hands. Very impressive.

Following that, we continued our tour through the departments overseeing movement and watch assembly. In the image below, a skilled watchmaker is fitting the completed swing system into the movement.

Watchmakers, fully focused, diligently assembling the movement. The level of concentration required to work with such tiny components and assemble them by hand is truly remarkable.

In this room, the last step of watch assembly takes place. It involves fitting the movement into the case, attaching the hands to the dial, and securing the strap. Following this, the watch is prepared for shipping.

At one of the tables, we saw the process of placing the hands on the dial of the Ahoi neomatik 38 date.

Here’s the finished product, on my wrist, straight from production: the Ahoi neomatik 38 date, recently introduced to the public.

On this table the person is conducting the last inspections, ensuring the dial is spotless and getting the watch ready for use.

Nomos production center in Schlottwitz

Then we moved to the Glashütte district of Schlottwitz, where Nomos has it’s production center. Here the individual parts of the company’s proprietary movements are manufactured and get finished.

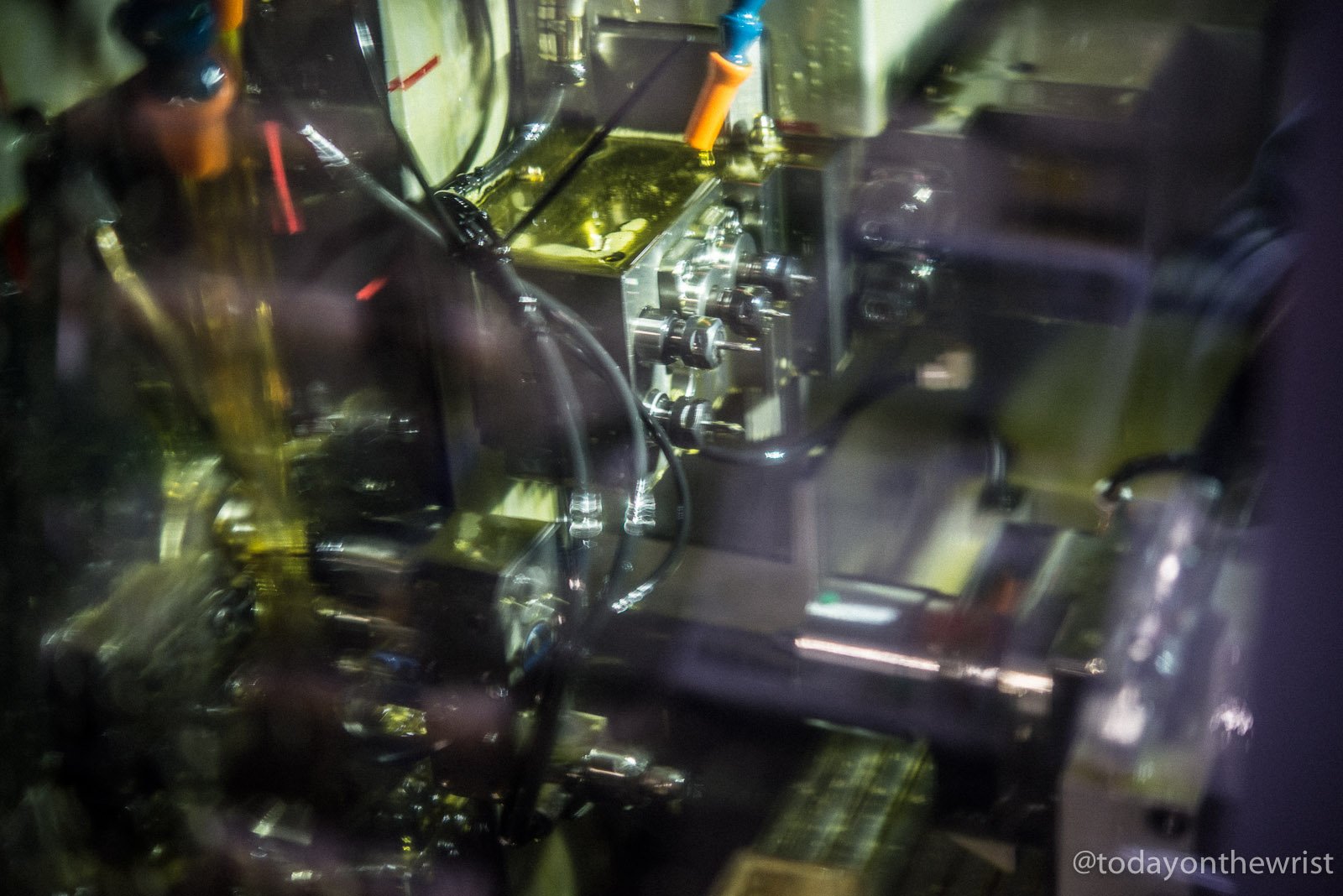

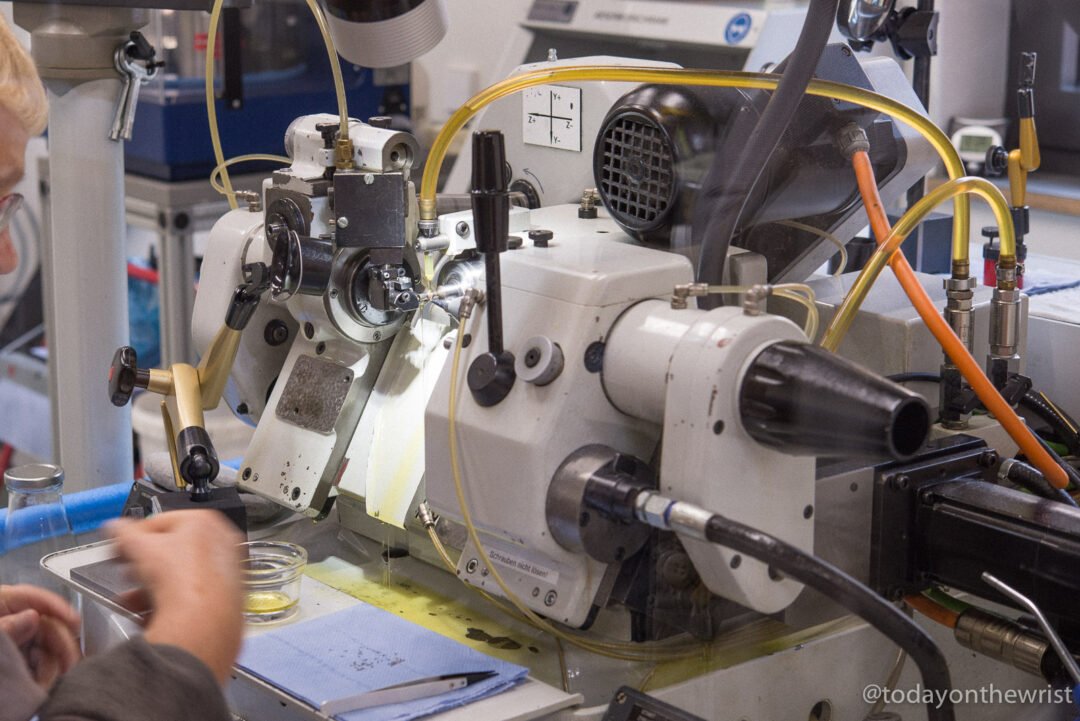

Here we observed machines precision-cutting raw materials and transforming them into movement parts. For example, in the pictures below, you can see a machine cutting tiny teeth with the help of an operator.

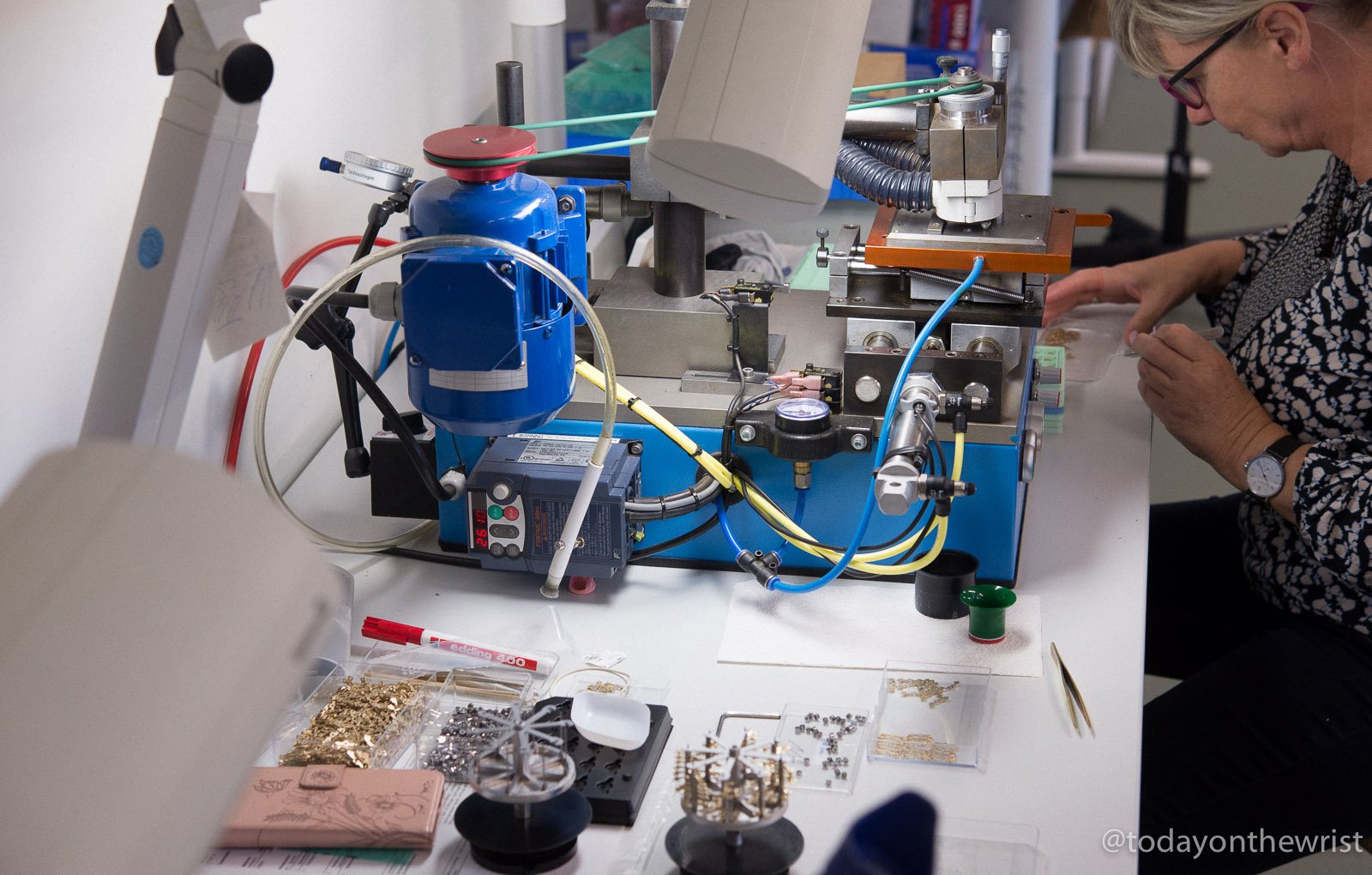

Finishing of the movement components is also happening in this building. Once this step is complete, the components are collected and transported to the chronometry building, where they are utilized in the assembly of a movement.

Here our visit to the manufactures came to the end, and it was truly impressive to witness the entire production process of Nomos watches. Seeing the extent to which they create components in-house and the significant amount of craftsmanship involved is remarkable, especially given the fact that we are talking about watches in the price range of 1,000 to 3,000 euros. I’ve always known that Nomos watches offer incredible value for money, and after this visit, I can wholeheartedly confirm it.

Nomos Forum

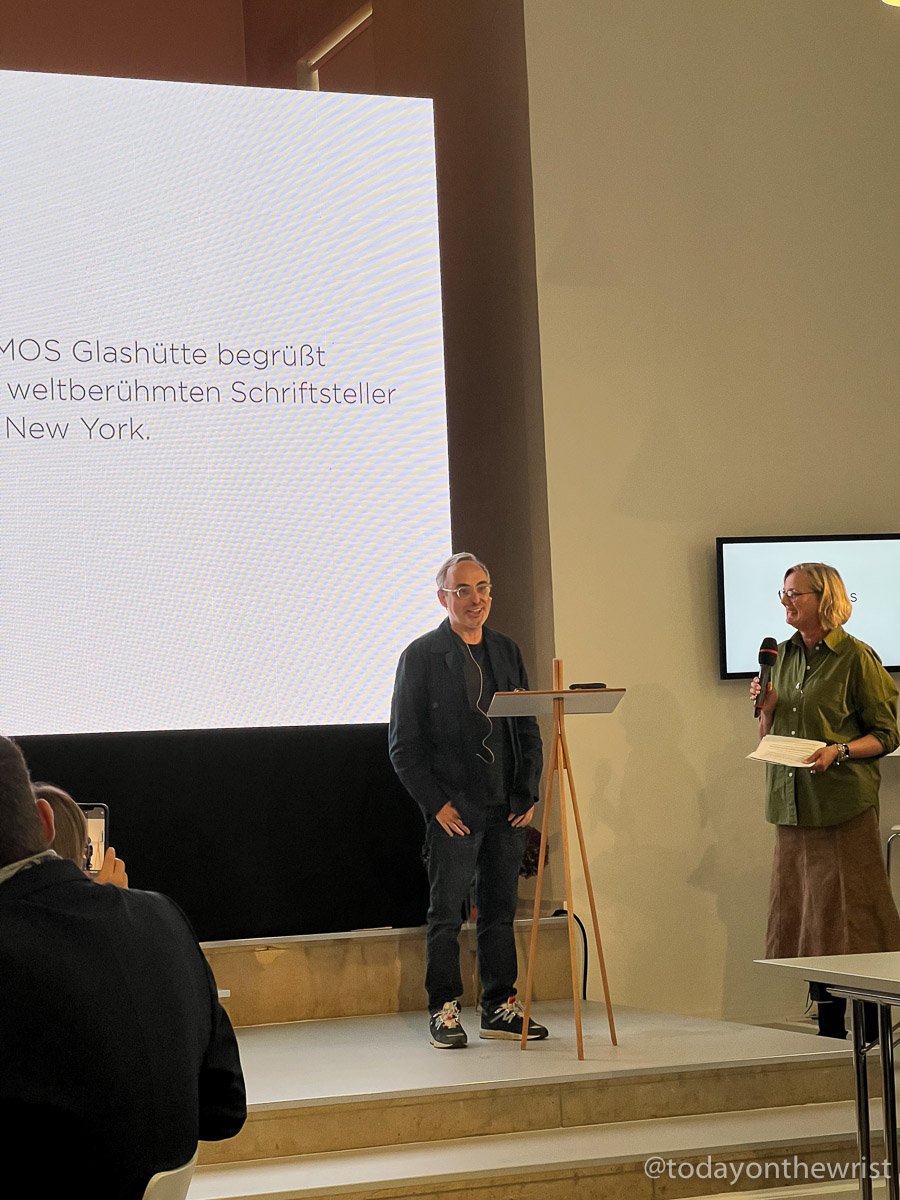

After that, we moved to the former church that Nomos purchased when it became available for sale, and it was the venue for the Nomos Forum. After the discontinuation of Baselworld, where Nomos had been a regular participant, the brand required an alternative platform for communication, sharing news and unveiling new products. Thus, the Nomos Forum was established. This event features a format in which watch journalists and enthusiasts that are active online gather in Glashütte once a year to gain insights into the brand’s activities.

One of the topics that we discussed during the Forum is importance of providing excellent service for the watches, a topic I wholeheartedly agree with. Nomos emphasized the need for servicing their watches every 5-6 years, ensuring both speed and affordability. As an added benefit, customers will receive a temporary watch while their timepiece is being serviced; it’s a specially designed watch for this purpose, and I must say, it looks quite cool. Additionally, we had the opportunity to explore some new watches that Nomos has in the pipeline.

One of the highlights was the new Nomos Club Sport neomatik 39 mm. I won’t deep dive into the details now since this watch deserves its own dedicated article. Stay tuned for more.

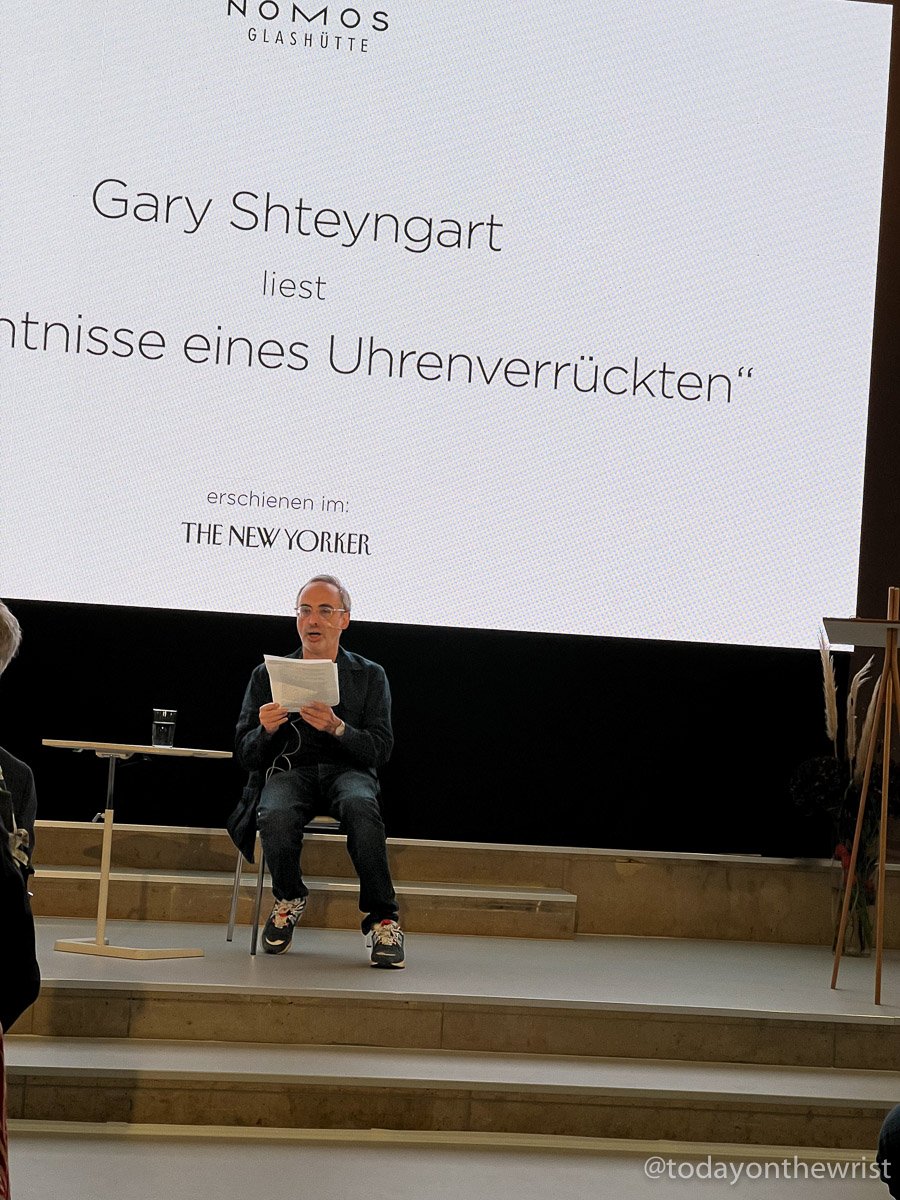

We also had a special guest that day, a watch enthusiast, a Nomos fan, and an author from New York, Gary Shteyngart. You might have come across him on Talking Watches on Hodinkee. He even treated us to a reading of his article for The New Yorker, where he shared his passion for watches and his deep affection for Nomos neomatik.

Our time with Nomos in Glashütte was truly fantastic. We got to see how watches are made, discuss our shared passion for timepieces, meet with fellow enthusiasts, and make new friends. Thanks Nomos for the invitation and the great format.

More details about Nomos watches on nomos-glashuette.com